January / February 2025

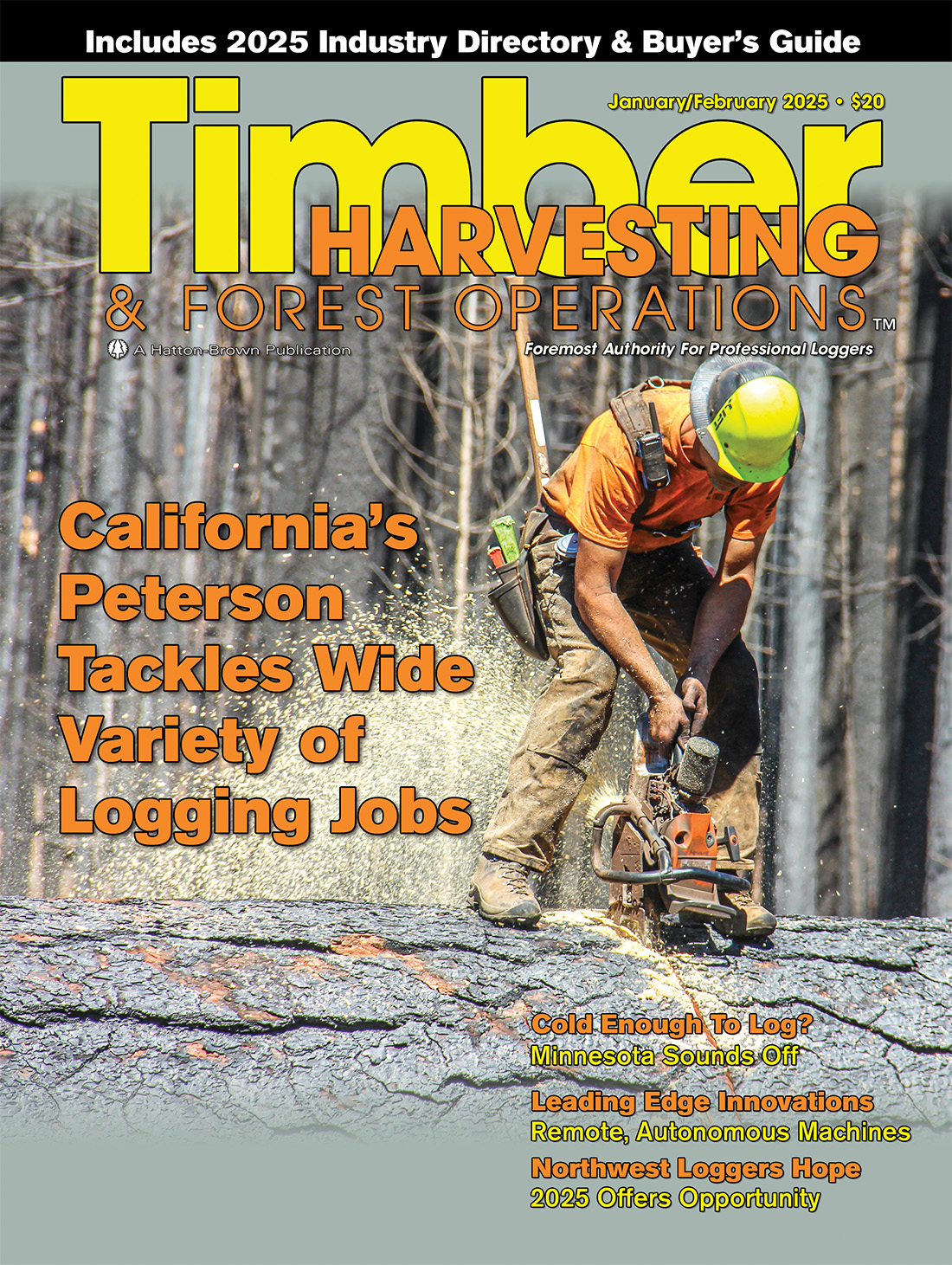

California’s Peterson Tackles Wide Variety of logging Jobs

California’s Zane Peterson runs a large and diversified operation.

INSIDE THIS ISSUE

COVER STORY

California’s Peterson Tackles Wide Variety of Logging Jobs

MY TAKE Investing in Fiber Opportunity

During the past few years we’ve been closely covering the significant shift in the U.S. pulp and paper indus- try and the impacts on loggers: The in- dustry is using less roundwood as re- cycled materials are utilized, and mar- kets for traditional sheet paper prod- ucts are sagging in the digital age. All regions of the U.S. have suffered paper mill and machine closures and cutbacks, and loggers who find them- selves operating in the procurement area of reduced fiber log demand are looking hard at alternatives but mostly hauling farther to move logs to facili- ties that are still open.

Newslines

- Oregon Logging Conference Offers New Logging Tech

- Groups Sue To Stop Montana Forest Project

- New California Sawmill Receives Boiler Grant

- Stimson, IDL Agreement Protects Idaho Forest

- Irving Acquires Maine’s Masardis Sawmill

- Johnny Boyd Dies At 62

- Great Lakes Loggers Mourn Passing of Carl Theiler

- USDA Begins Loan Program

- Allegheny WP Begins Selling Hardwood Mills

- Major Weyerhaeuser EWP Investment

MN Loggers Look At Weather Changes

The forest industry is the fifth largest manufacturing sector in Minnesota by employment, with most of the industry based in the northern part of the state. About 53% of the annual volume harvested is produced during the winter when soils are frozen.

Northwest Logger Outlook

- Seeking Opportunity

- Changing Markets, Misguided Policies

- Equipment Issues, Labor Concerns

NewTech

- Air Burners: Biochar Innovation

- Rotary Copperhead Saw Chain

- Forest Chain Protection

- Tigercat Biomass Tech: 6040 Carbonizer

- Deere L-II Skidder Innovations

- Iggesund Bars: Top Quality

- Percision Husky Grinder/Chipper

- ProLenc Log Load Binders

- Western Trailer: Forest Fiber Hauling

- TRYGG Netlink Forestry Chain

- Ponsse: Steep Slope Opportunity

- Bandit Blends Technology, Durability

Select Cuts

- As We (ALC) See It 2025: Can History Repeat Itself

- Drax May Supply Pellets To Pathway

- More Time Allowed To Prep for EUDR

- DG Fuels Selects SAF Site In Minnesota

Golden Oppertunities

Young north Cali Logger Zane Peterson seizes biomass/wildlife opportunities.

Story by: David Abbott

California has earned its reputation for being progressive on environmental consciousness, for better and/or worse. “The biomass side of the business has definitely been encouraged through the legislature,” Peterson admits, referencing the state’s Assembly Bill 901. “The state basically mandated power purchase agreements to keep those facilities running. It mandated that Pacific Gas and Electric Co. buy biomass power to keep fuel moving from the woods because our wildfire issue isn’t so much a fire issue as it is a fuel issue. We have way too many stems per acre and it’s way too hot and dry. So if we can reduce that by thinning, then it can survive wildfire. So it’s important to have an outlet for these biomass chips from these fuel reduction and fire prevention projects.”

The situation creates an opportunity for loggers like Peterson, though it’s more about public benefit than profitability, he acknowledges. “All the fuel reduction projects are subsidized through grant programs and that’s the only way we can make it work. It’s not a self-sustaining private market, so you only can do so much every year. A lot of the funds come from carbon offset sales.”

Federal timber sales account for 10% of Peterson’s business; 60% is contract logging for mills and the balance is in biomass chipping on fuel reduction projects.

Fuel reduction projects are so critical because the amount of fuel on the landscape makes it very unsafe for firefighters to get in. Part of the strategy is to build in fuel breaks to give firefighters a safe stronghold. “The more work we can do in the forest to thin things out, the better chance we have of containing (the fires),” Peterson believes.

Last fall, one Peterson crew was working to help clean up from the Park Fire, a massive blaze that devastated large portions of Butte and Tehama counties during late summer 2024. Peterson points out that this U.S. Forest Service job, the Park Fire Emergency Integrated Resource contract, is the first of its kind in terms of the federal government starting the project so soon after the fire so that fiber can be utilized. The goal is clearing hazardous dead trees to make the roadside accessible and safe for public use. Peterson’s crew removes and sells the fiber while it’s still valuable, which hasn’t been the case in the past. “Most Forest Service burned salvage jobs have not been put out in a timely manner, leaving the wood to go bad,” he says.

That is one of the challenges after big fires: getting salvaged wood into the mills quickly. The Park Fire job, in a mixed conifer stand in mid-range elevation (3-5,000 ft.), is all-hands-on- deck, with as many as seven logging contractors working in this fire scar, racing to move the wood before it goes bad. The clock is ticking; they have about 18 months from the time it burned until the fiber is no longer suitable for manufacturing. Because of the dry climate, wood rot isn’t as much of an issue as bug infestation. Once the timber is damaged and distressed, flathead bores move in and start eating holes in the wood, damaging its structural integrity.

WANT MORE CONTENT?

Spanning seven decades since its inception in 1952, Timber Harvesting highlights innovative and successful logging operations across the U.S. and around the world. Timber Harvesting also emphasizes new technology and provides the best marketing vehicle for the industry’s suppliers to reach the largest number of loggers in North America and beyond.

Call Us: 800.669.5613