Veriga Tracks

With today’s highest capacity skidders, which utilize six-wheel drive and a large grapple, tracks are commonly used to improve traction and performance. This is particularly true on soft or wet terrain, if minimal impact on the forest floor is needed, and to minimize fuel consumption. Tracks have a much larger contact area with the ground compared to tires alone or tires with chains, which enhances the stability of the machine with greater loads. There is greater force transmission, making the machine more efficient. Tracks also prolong the life of the tires regardless of what ground they are working on.

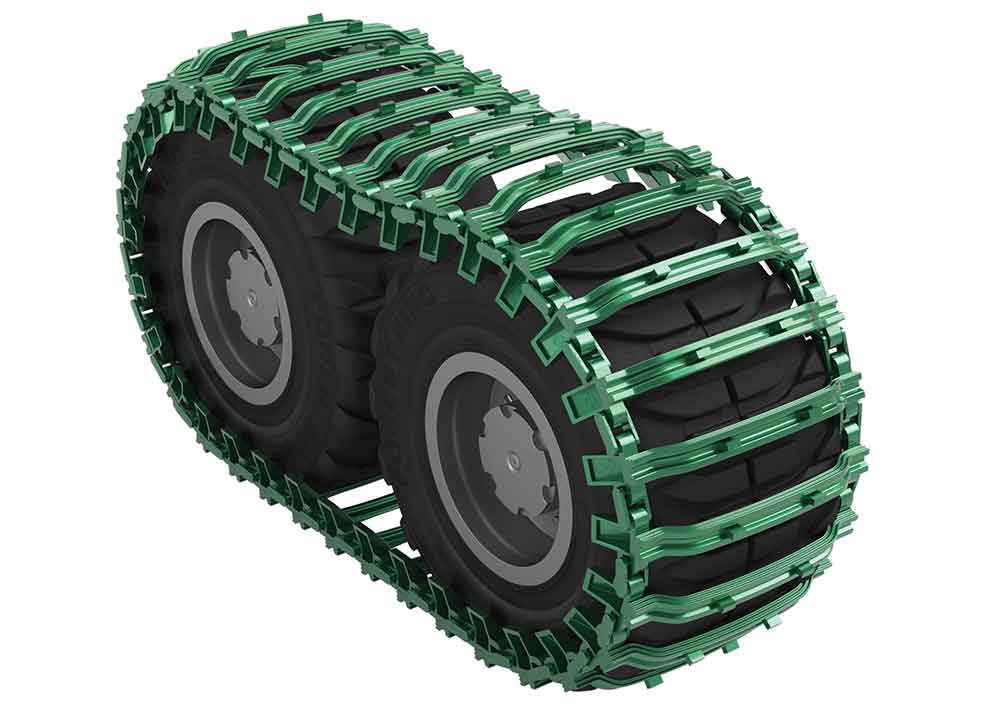

Veriga produces a track that is well suited for this application. The GreenTRACK Groove has a thick plate with a double-grouser profile that comes standard with an aggressive double spike pattern. It also comes standard as an extended bogie track, required by most 6-wheeled grapple skidders. Veriga’s link system for this track is a 30mm x 35mm oblong design that reduces surface wear and extends service life, as well as a twist inhibiting side rail. Veriga GreenTRACK plates utilize a rolled profile, not castings, ensuring even and adequate hardness throughout the entire profile constructed from a boron alloy steel. All GreenTRACK tracks are put through a specialized heat treatment process to get an optimized ratioof hardness and toughness. Hardness for abrasion resistance and toughness ensures the material is not fragile and won’t crack under higher loads. When purchasing your new 6-wheeled skidder or replacing the tracks on the one you have been operating, consider Veriga GreenTRACK Groove as an option to give you great performance and service life.

Veriga produces a track that is well suited for this application. The GreenTRACK Groove has a thick plate with a double-grouser profile that comes standard with an aggressive double spike pattern. It also comes standard as an extended bogie track, required by most 6-wheeled grapple skidders. Veriga’s link system for this track is a 30mm x 35mm oblong design that reduces surface wear and extends service life, as well as a twist inhibiting side rail. Veriga GreenTRACK plates utilize a rolled profile, not castings, ensuring even and adequate hardness throughout the entire profile constructed from a boron alloy steel. All GreenTRACK tracks are put through a specialized heat treatment process to get an optimized ratioof hardness and toughness. Hardness for abrasion resistance and toughness ensures the material is not fragile and won’t crack under higher loads. When purchasing your new 6-wheeled skidder or replacing the tracks on the one you have been operating, consider Veriga GreenTRACK Groove as an option to give you great performance and service life.

Latest News

New From Komatsu: 951XC-1 Harvester

New From Komatsu: 951XC-1 Harvester Komatsu is launching a new model of its largest harvester, the 951XC-1, with eight driven wheels to drive traction, maneuverability and stability in steep, soft...

American Loggers Council Letter Urges Trump To Act Quickly

American Loggers Council Letter Urges Trump To Act QuicklyAmerican Loggers Council along with American Biomass Energy Assn. and Forest Landowners Assn. has circulated a “stakeholder” letter...

WANT MORE CONTENT?

Spanning seven decades since its inception in 1952, Timber Harvesting highlights innovative and successful logging operations across the U.S. and around the world. Timber Harvesting also emphasizes new technology and provides the best marketing vehicle for the industry’s suppliers to reach the largest number of loggers in North America and beyond.

Call Us: 800.669.5613