New From Cat: 558 Forest Machine

The new Cat 558 next generation forest machine features several design upgrades for boosting production. “The previous 558 was the best in its class for moving timber with power and reliability,” says Brent Uitermarkt, vice president for Caterpillar’s forestry products. “The new 558 next gen machine builds on that by being even more productive. Plus, it has added benefits of greater comfort and safety, and owners will spend a lot less time and money on maintenance.”

Available in Log Loader and General Forest configurations, the new 558 is powered by a Cat 7.1 engine that generates 25% more power than the previous series. Add in the machine’s new electrohydraulic control system that produces 30% more swing torque and 15% more travel power and tough, and hilly work becomes easier to accomplish.

Smart mode automatically matches engine and hydraulic power to working conditions to help do that work with maximum fuel efficiency. Also, with cold-start capability of -25˚ F (-32˚ C) and high ambient temperatures reaching 126˚ F (52˚ C), the machine can work year-round.

The new Certified Forestry cab with its reinforced structure and thick polycarbonate windshield enhances operator safety. Available in a choice of rear or side entry, the cab’s interior space is 25% larger, allowing most operators to stand without hitting their head. Field of view from the standard heated and cooled seat is 50% better due to narrower cab pillars, larger panoramic windows, and a flat engine hood.

Operators have multiple options for starting the 558’s engine, including an easy-to-reach push button, Bluetooth key fob, or unique Operator ID function; Operator ID allows each operator to quickly program and store their own machine settings and attachment function preferences.

Compared to the previous model, the 558 next generation will consume 50 fewer filters over the course of 12,000 hours, which contributes to lowering maintenance costs by up to 15%.

Fuel filters feature a synchronized 1,000-hour change interval—double the service life of the previous model. A new hydraulic oil return filter improves filtration and delivers a 3,000-hour service life, which is 50% longer than previous designs.

Product Link technology captures critical operating data, fault codes, and machine location information to boost fleet management efficiency.

Visit cat.com

Latest News

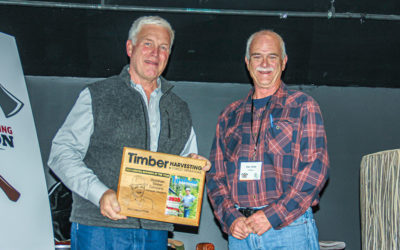

American Loggers Council Gathers In Maine

Loggers and industry advocates from throughout the U.S. (and beyond) converged on the little town of Newry, Me., October 4-6 for the American Loggers Council’s 2023 Annual Meeting. Maine’s own Andy Irish ended his 2022-2023 term as ALC President by hosting the event in his home state, offering his peers from other regions a sample of the local culture, cuisine and logging techniques…

Weyerhaeuser Goes After Carbon Credits

Weyerhaeuser Co. announced it has received approval from the American Carbon Registry for its Improved Forest Management (IFM) carbon credit project in Maine. Covering approximately 50,000 acres and verified through a third-party auditor, the Kibby Skinner IFM Project is the first issuance of credits for Weyerhaeuser through the voluntary carbon market…

WANT MORE CONTENT?

Spanning seven decades since its inception in 1952, Timber Harvesting highlights innovative and successful logging operations across the U.S. and around the world. Timber Harvesting also emphasizes new technology and provides the best marketing vehicle for the industry’s suppliers to reach the largest number of loggers in North America and beyond.

Call Us: 800.669.5613